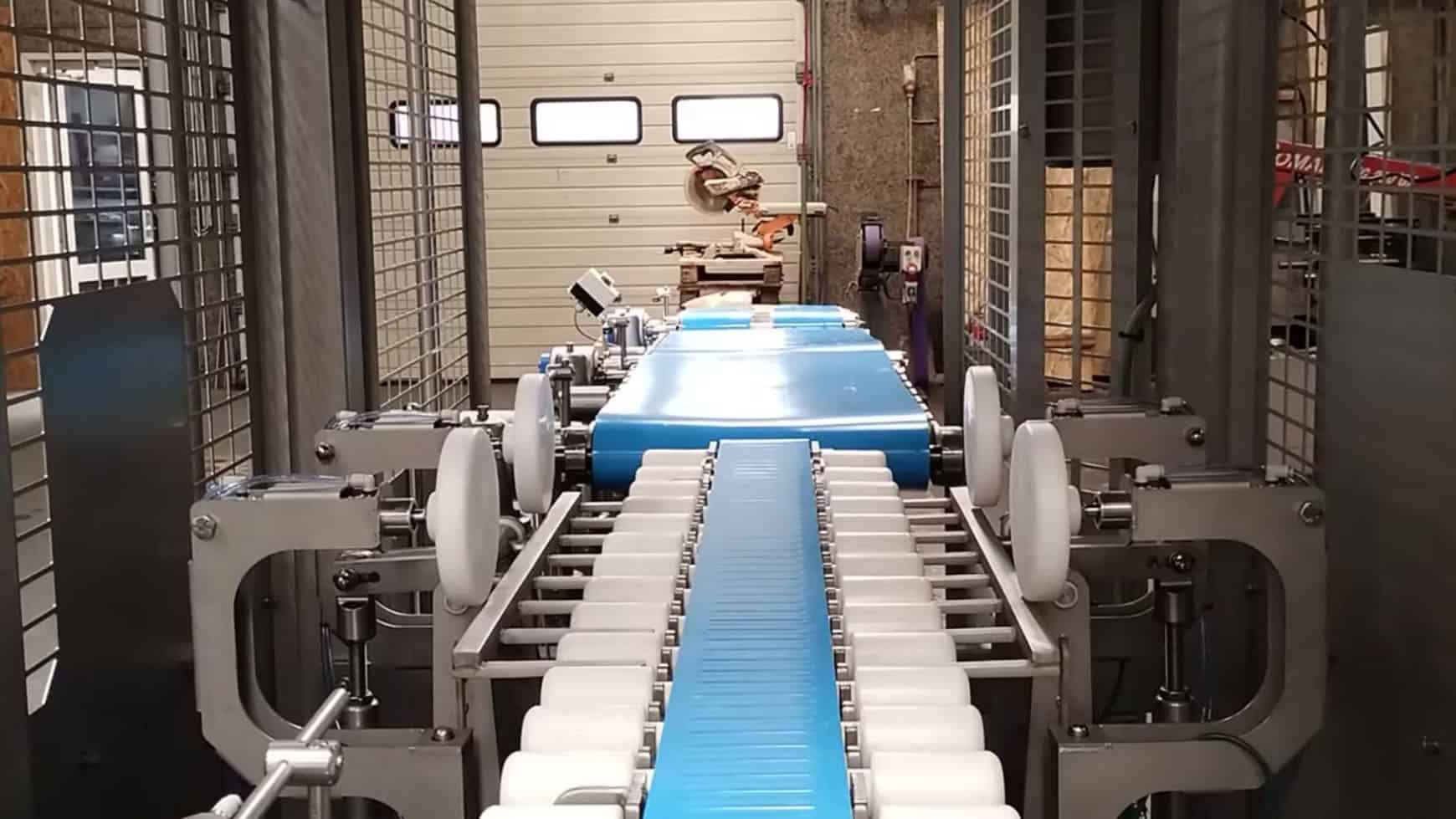

Internal transportation is undoubtedly an important element of infrastructure and logistics processes affecting the profitability of production. Automation enables efficient transportation of products, facilitates assembly, eliminates errors, supports quality control, speeds up packaging and stacking of goods.

Automation of production and warehousing logistics processes for every industry

We are experts in implementing solutions that improve internal transportation and increase production efficiency.

GIPO – INNOVATIVE PROCESS OPTIMIZATION

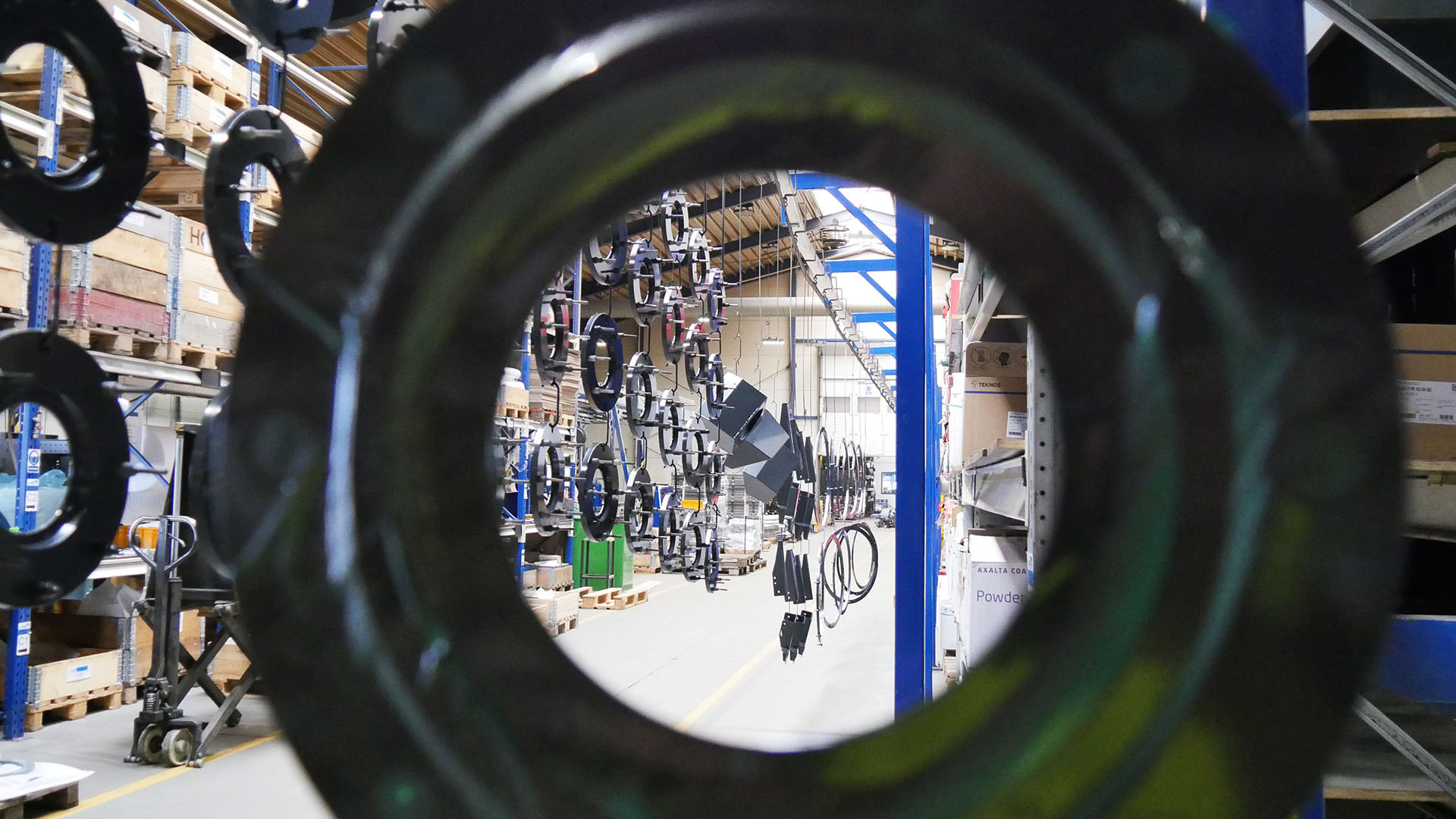

The dynamic development of the industry and the high level of competition make process optimization a major factor determining a company’s position in the market. Gipo’s core business is the design and manufacture of dedicated transport solutions, conveyors, logistics systems and special machines.

BENEFITS OF INTRODUCING AUTOMATION

Gipo focuses on creating solutions that optimize production and warehouse processes in terms of functionality, safety, efficiency and cost savings. Here are some key benefits of implementing automation for every industry.

TIME

Reducing the time it takes to complete production tasks, affects company profitability and product quality. Time is a very important issue in the production process, especially in refrigerated food transportation.

WORK SAFETY

At the design stage of Gipo systems, we pay special attention to the issue of safety. Automation of material handling systems in factories and warehouses eliminates the need for manual lifting of heavy objects, reducing the risk of accidents and injuries to workers.

SCALABILITY

Automating material handling makes it easy to adapt to changing needs and expand factory operations. We design solutions so that Gipo customers have the ability to upgrade or expand material handling systems in the future.

ACCURACY AND PRECISION

Gipo systems are precisely programmed to perform specific tasks, minimizing the risk of errors. This helps achieve higher quality and accuracy in production processes.

MONITORING AND OPTIMIZATION

Automation of goods transport enables close monitoring of logistics processes. Data on the flow of goods, lead times and productivity can be collected and analyzed, allowing areas for optimization to be identified and decisions to be made based on current data.

COMPETITIVENESS AND COMPANY IMAGE

Implementing and improving automation in internal transportation contributes to the company’s competitiveness in the market. Faster production rates, lower costs and higher product quality, as well as increased competence and qualifications among employees, affect the company’s reputation.

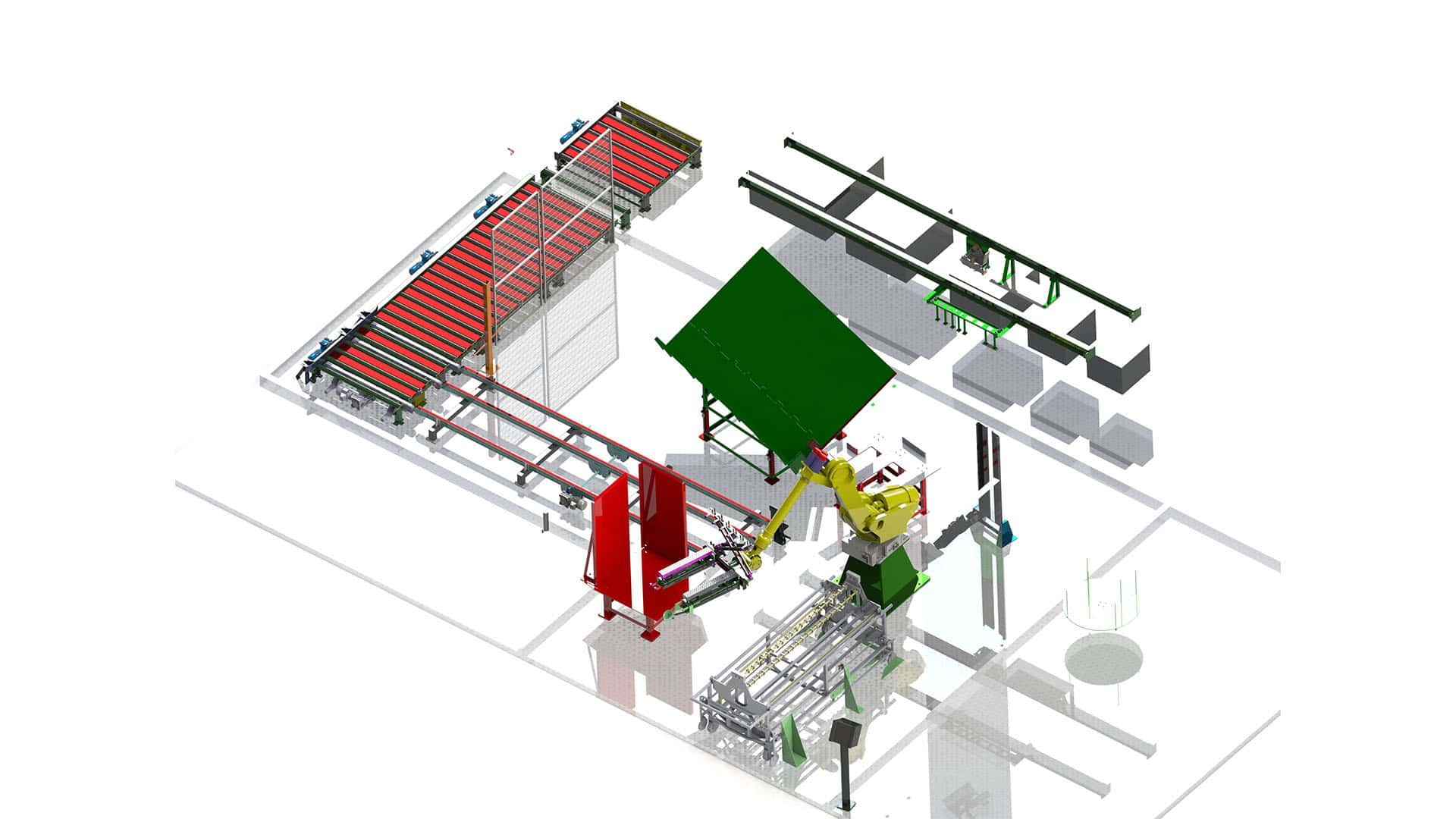

FROM CONCEPT, THROUGH DESIGN AND IMPLEMENTATION

We act as a comprehensive supplier, guaranteeing pre-design advice and consultation. We carry out complex dedicated automation systems and individual equipment, transport lines, sorting lines, assembly line, packaging lines, palletizing solutions, pallet warehouses, automatic trolley, tailor-made conveyors, turning devices, custom KANBAN racks, semi-automatic assembly table, scissor lift and many more.

WE OPERATE COMPREHENSIVELY AND IN ONE LOCATION

Our manufacturing facility allows us to carry out all processes in one place, this shortens the time for projects and allows us to maintain competitive prices. From the concept phase, through the design stage, to full implementation, we offer personalized material handling solutions for factories and warehouses. At Gipo, we design entire logistics processes and integrate equipment into existing transportation lines. We implement designs developed and optimized by our engineers.

According to the customer’s needs, we are able to implement any project including transportation, installation, SAT and operator training.