Outsourcing is a fundamental element in the operating strategy of most companies. Every industry uses outsourcing services. Outsourcing involves delegating tasks and functions to external companies that specialize in a particular field. Outsourcing is considered by entrepreneurs to be a key aspect of efficient operation of their companies.

WHY USE GIPO’S OUTSOURCING SERVICES

Since 2006, we have completed outsourcing assignments for more than 5,000 companies in various industries. By using GIPO’s outsourcing services, you can increase the efficiency of your business, reduce costs, focus on your company’s core competencies and benefit from the knowledge and resources of our specialists.

Gipo provides a wide range of outsourcing services:

- Metalworking services

- Parts manufacturing

- Machine and equipment manufacturing including wiring, connection and commissioning

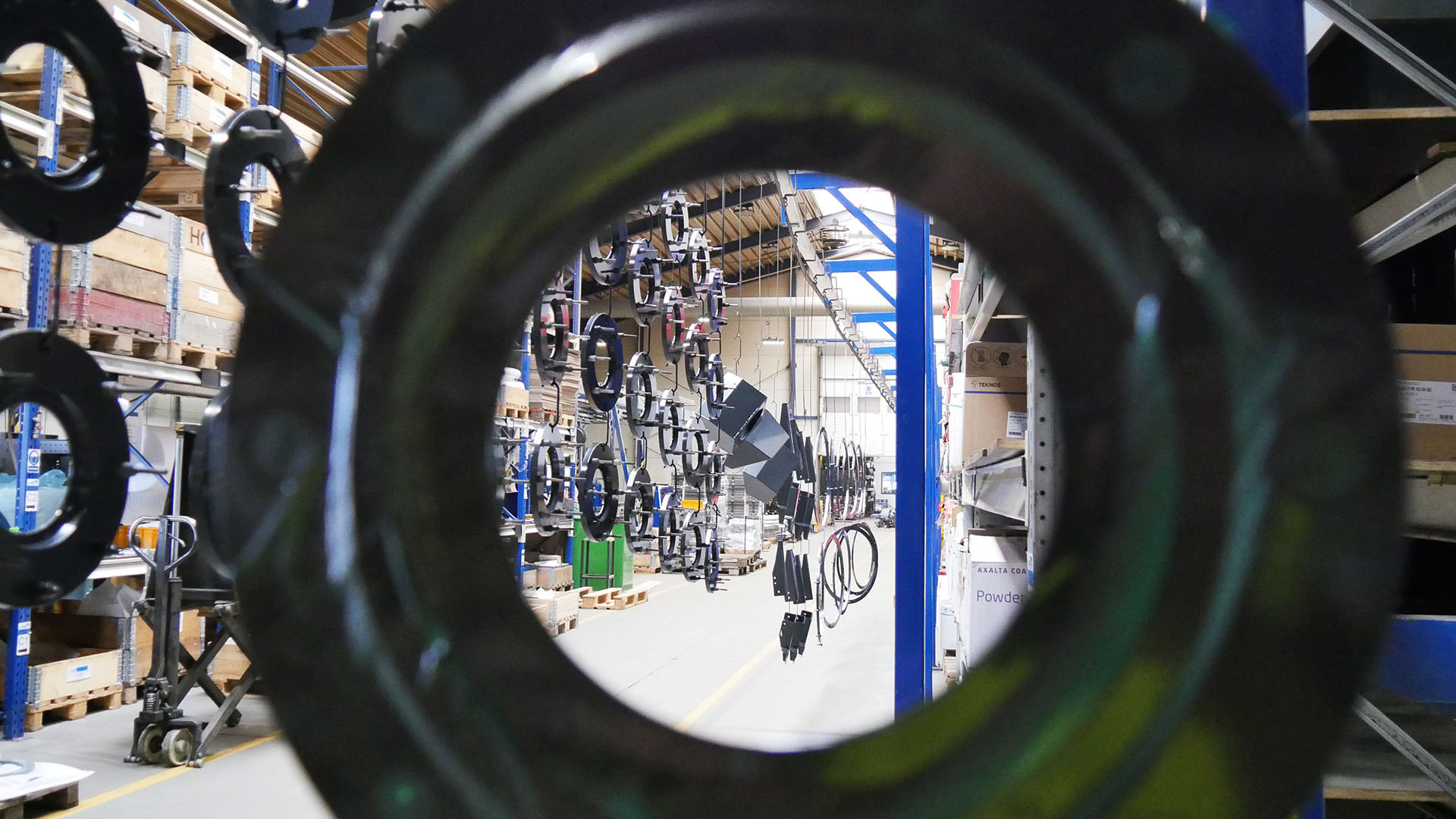

METALWORKING OUTSOURCING AT GIPO

As a provider of outsourced metalworking and metal parts manufacturing services, we have a very wide range of offerings for many different industries. From structural steel, stainless steel and aluminum, we manufacture components, machine and equipment parts and complete structures including access platforms, non-powered carts, structural components and much more

Machinery park in GIPO »

Range of services:

- CNC Cutting

- CNC Bending

- Turning / CNC Turning

- CNC Milling

- Welding

- Coating

- Spray painting

- Design

- Ce Marking

- Installation

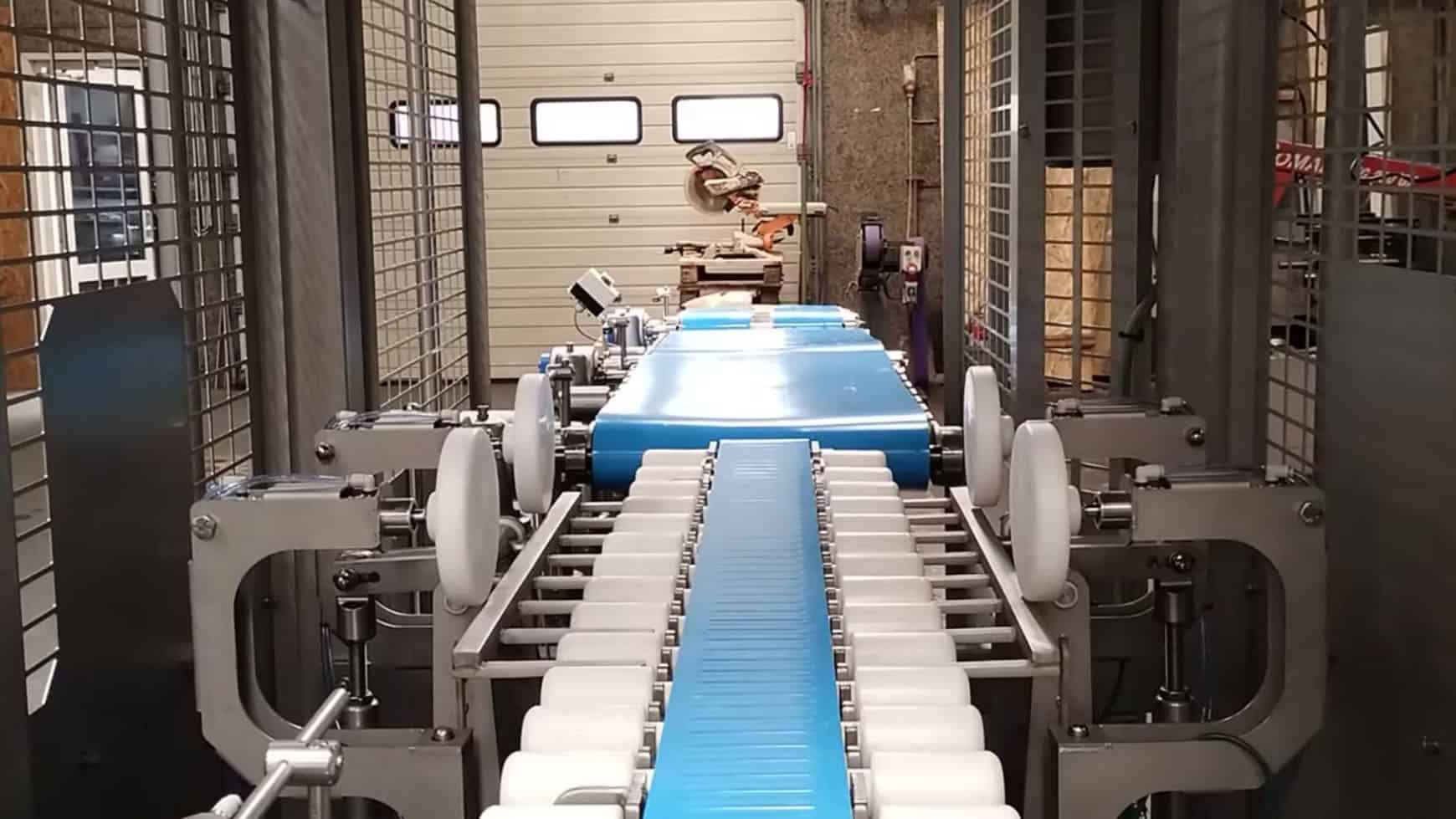

PARTS MANUFACTURING & PRODUCTION OF MACHINERY AND EQUIPMENT INCLUDING WIRING, CONNECTION AND COMMISSIONING

Our customers are mainly companies engaged in the production of machinery and equipment – this involves complex production processes. Understandably, most companies are not able to perform all production processes in their own factories.

Delegating tasks externally is an important part of most companies’ operations. In today’s business environment, many companies focus on their core competencies and strategic areas. Complex production processes that require specialized knowledge, experience and advanced infrastructure are entrusted to external companies. This allows efficient use of resources, avoids the need to invest financial resources in business expansion and maintains operational flexibility.

Cooperation with GIPO is based on trust. The orders we execute in many cases are covered by a non-disclosure agreement.

Here are some of the selected industries and implementations. We work with companies in the renewable energy industry: production of boxes for windmills with wiring. For the oil and gas extraction industry we have made: Air-conditioning units for oil rigs with air purification and air methane control functions; Oil pumping stations for oil tankers, which are used for filtering and oil recovery. For the textile industry: carpet manufacturing equipment. Cosmetics industry: candle production equipment. Plastics and packaging industry: Personalized industrial hose wrapping device; Labeling device; Chain coil unit for combining individual parts into chain coils. Agricultural industry: big bag packaging machine; Agricultural machinery parts for Green Chip; Agricultural machinery parts for AGCO A/S Randers Denmark. Weighing equipment industry: Scales and weighing systems for static, dynamic and continuous weighing for Jesma Vjeteknik A/S.

We also accept orders for series production of:

Chain conveyors, roller conveyors, turntables with roller conveyors, belt conveyors and may others.

We work according to the guidelines and based on the customer’s designs, and implement designs developed and optimized by our engineers.

Quality at GIPO

We supervise production at every stage using advanced measurement methods and techniques. We use NDT methods to detect any defects or irregularities in welded joints, castings and forged parts.

We work based on management systems:

- Quality Management System in accordance with the PN-EN ISO 9001:2015 standard

- Environmental Management System in accordance with the PN-EN ISO 14001:2015 standard

- Occupational Health and Safety Management System in accordance with the PN-ISO 45001:2018 standard

Here are some of the main reasons why companies choose to outsource at GIPO

COST SAVINGS

One of the most important reasons companies choose to outsource at GIPO is the potential for significant cost reductions. Outsourcing allows manufacturers to avoid investing in sophisticated infrastructure, specialized personnel and technology, resulting in lower production costs.

FOCUSING ON CORE COMPETENCIES

By outsourcing at Gipo, our clients can focus on developing and improving their core competencies. This allows for a more efficient use of resources and energy, which can lead to greater innovation and competitiveness. In today’s business environment, many companies focus on their core competencies and strategic areas, and can outsource complex production processes to specialists in the field. By outsourcing these processes to Gipo, businesses can focus on product development, marketing, sales and other areas critical to their success.

FLEXIBILITY AND SCALABILITY Outsourcing at GIPO enables manufacturers to flexibly adapt to changing market conditions. Our clients can quickly adjust production to meet changing demand, which is more difficult for in-house manufacturing where infrastructure investments are fixed and difficult to modify. At GIPO, we have an extensive machinery park, and we operate comprehensively and in one place, so we have oversight of all production processes.

ACCESS TO SPECIALIZED KNOWLEDGE AND EXPERIENCE

At Gipo, we have specialized knowledge and many years of experience in providing outsourcing services for any industry. Since 2006, we have completed outsourcing assignments for more than 5,000 companies in various industries.

***

References from CEO Ole Jensen AGCO A/S

AGCO A/S Randers Denmark is part of the AGCO CORPORATION, which is one of the world’s largest manufacturers and distributors of agricultural machinery. The company’s brands are sold in more than 140 countries all over the world and the leading brands are: Massey Ferguson, Valtra, Challenger and Fendt.

“We have outsourced our entire production and now we only handle the assembly of the large agricultural machines in Randers. This has made our employees highly specialised in assembly. By outsourcing thousands of different elements, we become highly dependent on competent subsuppliers who make on-time deliveries and comply with our strict quality requirements. Gipo was able to fulfil our expectations. – Gipo has focus on the customers and they are extremely flexible. This is true regardless of whether the production comprises a few elements or a large industrial production. We also use Gipo as a proactive cooperation partner for development of new systems and processes. We make high demands on our suppliers and can warmly recom- mend cooperation with Gipo. They are qualified, compe- tent people who keep their promises”.

***

References from CEO Palle Serup, Jesma Vejeteknik A/S

Jesma Vejeteknik A/S is engaged in development, production and sale of a wide range of advanced scales and weighing systems for static, dynamic and continuous weighing. Our customers are primarily found in the food industry, the grain and feedstuff industry and the chemical/technical industry.

“It goes without saying that our products need to comply with numerous quality requirements. We are subject to Danish and foreign certification requirements and consequently we need to have competent suppliers who can contribute to the develop- ment of new solutions. Furthermore, they need to be able to guarantee professional and optimum realisation of the projects. We have only positive things to say about our cooperation with Gipo. The employees at Gipo are top profes- sional and the cooperation runs smoothly.”